My first 3D printer, the Makerfarm Prusa i3v, was given to me back in 2015. Originally, it accepted 3mm PLA or ABS filament and it used a geared drive on the X-axis carriage. Last summer I set out to make some major improvements which included:

- Converting to 1.75mm filament for additional flexibility and reduced cost

- Support for flexible filaments such as TPU

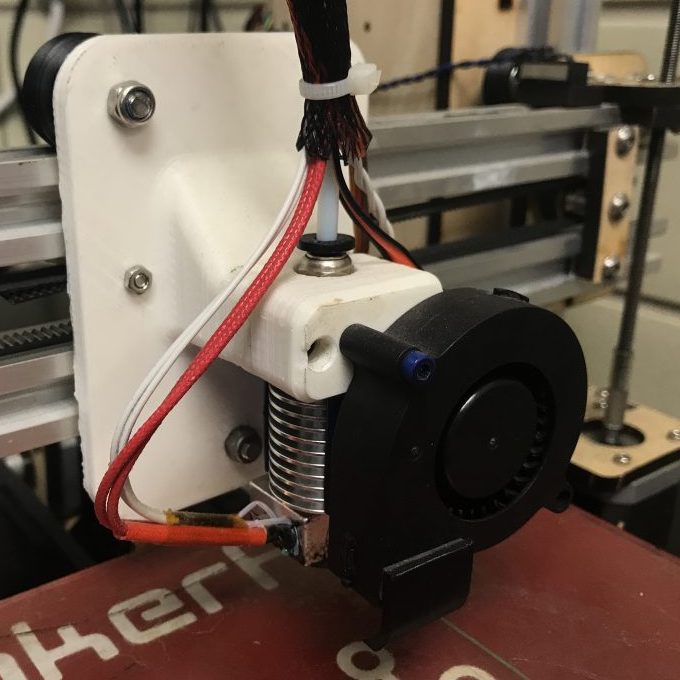

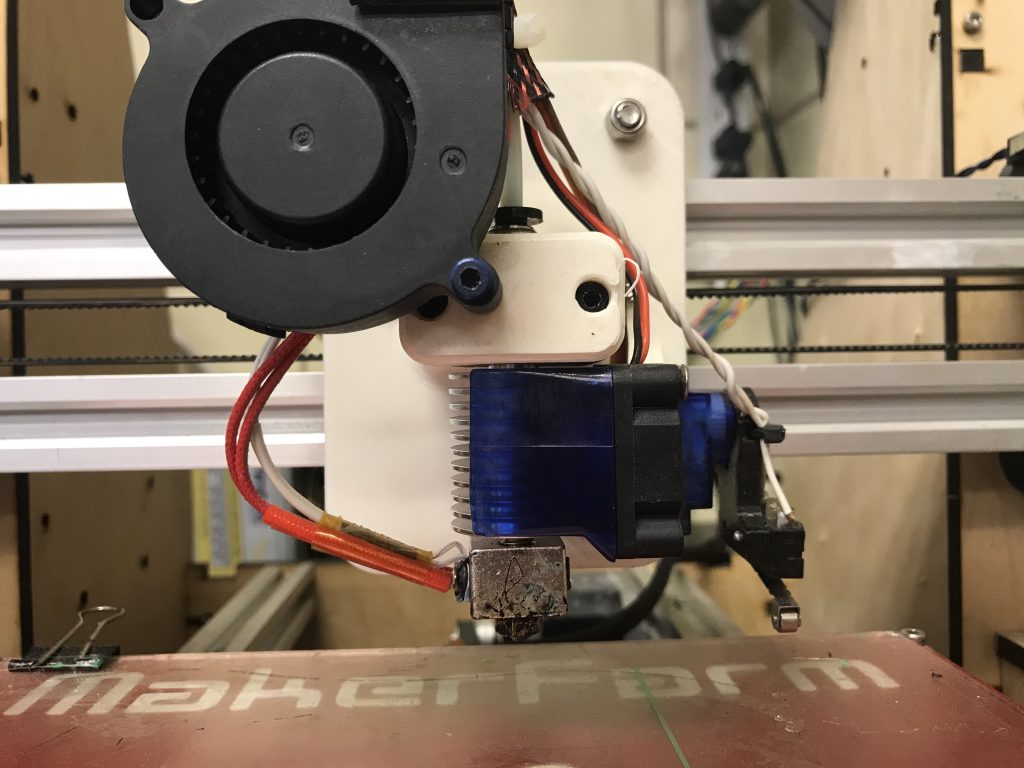

- Bowden tube, direct drive extruder to reduce X-carriage mass and improve accuracy.

- Better part cooling fan

- Z-axis probe with servo mount for print-bed leveling

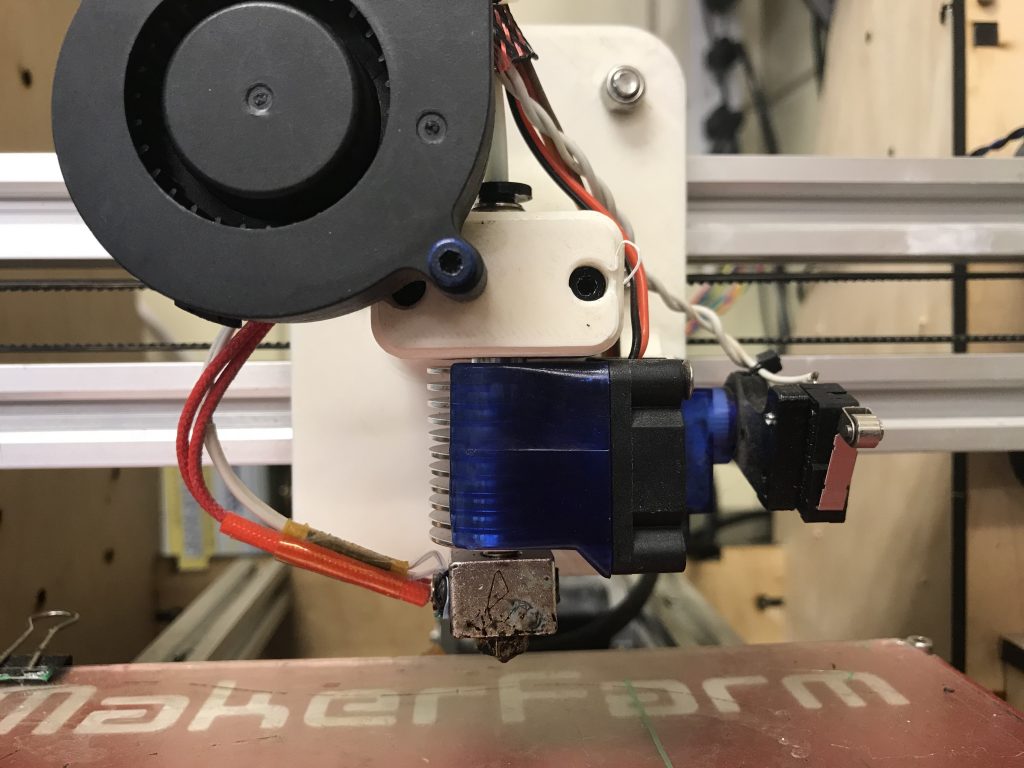

I chose to use the popular E3D v6 1.75mm extruder with Bowden tube. I also purchased a small blower fan instead of the axial fan that was originally on the printer. Finally, I added a small 9 gram servo and microswitch for bed leveling. All of these parts were mounted on a new X carriage that I designed and printed.

The Z-probe if mounted on a small printed bracket attached to the servo. During probing, the probe is in the down position. Once printing starts the probe rotates to a position above the print head.

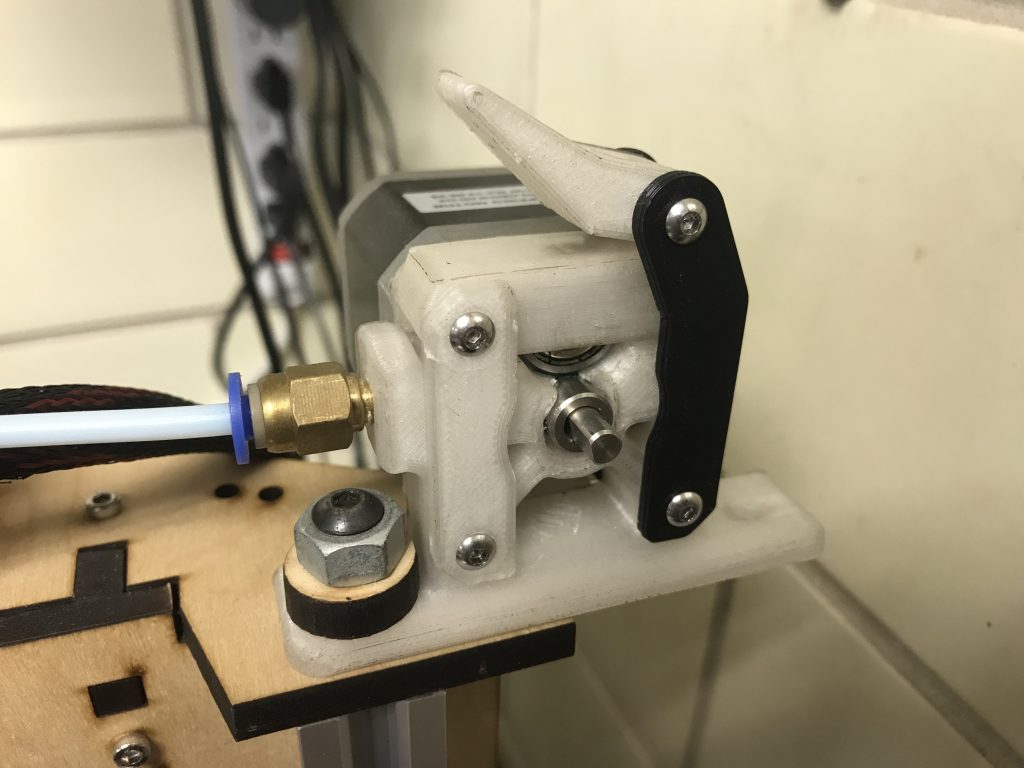

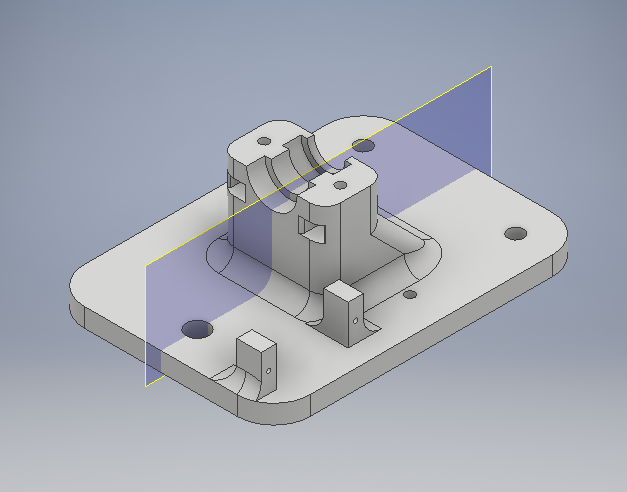

The filament drive is mounted on top of the printer. I used a design I found on Thingiverse